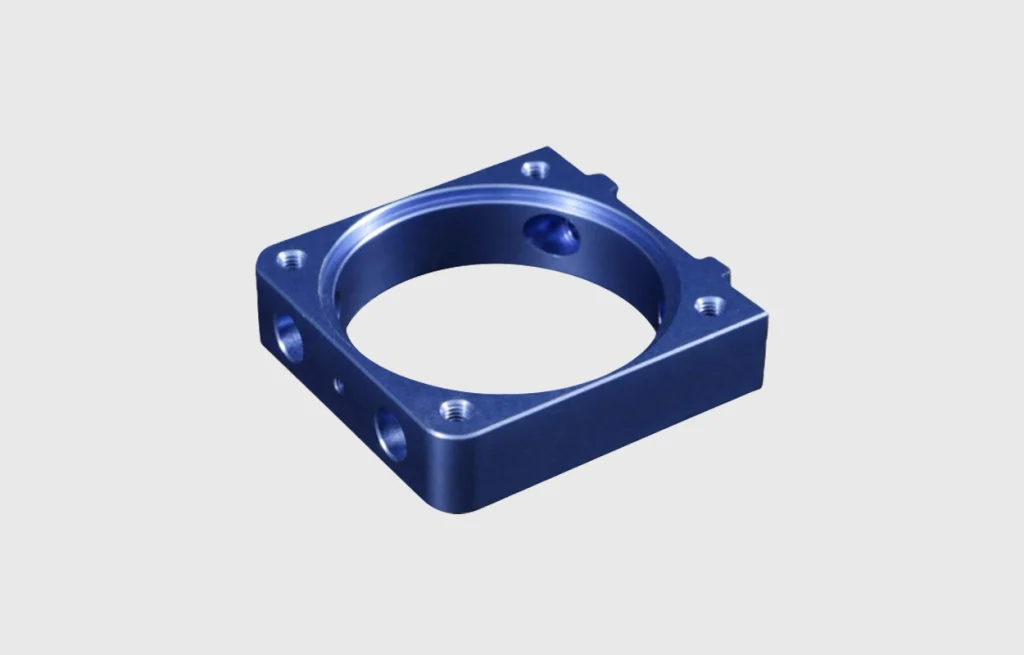

CNC machining technology

CNC machining services, including CNC milling, CNC turning and CNC routing, can deliver a wide range of products, from rapid prototyping to high-quality production parts.

CNC machining service

Accelerate your prototyping, product development, and manufacturing processes with efficient methods for obtaining precisely machined parts. Receive parts in just 3 days; 95.4% of orders arrive on time and are completed.

Incredibly precise machining

We guarantee cutting and positioning tolerances of +/- .005 inches (0.12 mm) or higher.

3-axis, 3+2-axis and 5-axis functions

We’re ready to process anything you dream of! It’s about to turn!

Smooth sorting, smooth surface

All CNC milled parts are treated with media blasting using our proprietary 360-degree micro-finishing process (machining finish is available upon request).

3D rapid turnover

Machined parts will be shipped within 3-7 days, depending on the order quantity.

Metal material processing

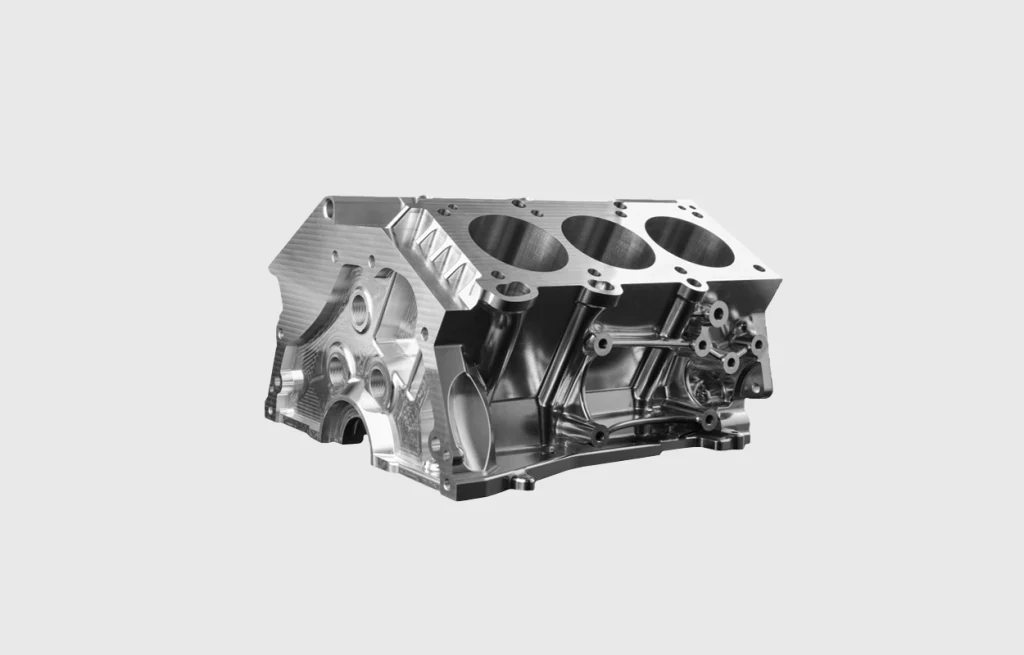

Aluminum Alloy

Aluminum alloys are well known for their lightweight properties, excellent corrosion resistance, high thermal conductivity, and varying strength depending on alloy composition. They offer outstanding machinability and enable high production efficiency.

Grades: 2007, 2017A, 5083, 6060, 6061, 6082, 7075, etc.

Applications: Aerospace components, automotive parts, sheet metal products, structural parts.

Stainless Steel

Stainless steel is renowned for its excellent corrosion resistance, high strength, and good heat resistance, making it ideal for parts requiring structural stability and high surface quality. It also offers good weldability and wear resistance, suitable for precision machining and long-term use.

Grades: 201, 304, 316, 316L, 420, 430, etc.

Applications: Medical devices, food processing equipment, mechanical parts, chemical equipment, structural components.

Brass

Brass features excellent electrical and thermal conductivity, along with outstanding machinability, making it a highly efficient material for CNC processing. It provides a smooth surface finish, good aesthetic appearance, and reliable corrosion resistance.

Grades: H59, H62, H65, C36000, etc.

Applications: Electrical connectors, valve components, precision hardware, pipe fittings, decorative parts.

Steel

Steel is known for its high strength, good toughness, and wide applicability, meeting the requirements of high-load and wear-resistant components. Its mechanical properties can be further enhanced through heat treatment, making it suitable for complex and high-strength parts.

Grades: Q235, 45#, 20Cr, 40Cr, SCM415, SCM420, etc.

Applications: Mechanical structural parts, transmission components, mold parts, automotive components, industrial equipment parts.

Titanium Alloy

Titanium alloys are characterized by high strength, low density, and exceptional corrosion resistance, maintaining stable performance under extreme conditions. With excellent biocompatibility, they are ideal for applications where weight reduction and reliability are critical.

Grades: TA1, TA2, TA5, TC4 (Ti-6Al-4V), etc.

Applications: Aerospace components, medical implants, precision instruments, high-end equipment, chemical processing equipment.

Non-Metal CNC Machining

ABS

ABS is widely used in CNC machining due to its high tensile strength and excellent toughness. It can be machined into parts with outstanding impact resistance, wear resistance, and flame-retardant properties, while also providing a good machined surface finish. ABS is commonly used as a metal replacement in automotive and marine applications.

Polypropylene (PP)

Polypropylene is lightweight and offers excellent chemical resistance and good fatigue performance, making it suitable for parts requiring corrosion resistance and flexibility. With low moisture absorption and good dimensional stability, it is widely used in chemical and industrial applications.

PPS

PPS (Polyphenylene Sulfide) is a high-performance engineering plastic known for its excellent high-temperature resistance, chemical resistance, and dimensional stability. It maintains reliable mechanical properties even in harsh environments, making it ideal for high-precision CNC machining.

Polycarbonate (PC)

Polycarbonate is well known for its high transparency and exceptional impact resistance, along with good heat resistance and dimensional stability. It is suitable for precision components that require high strength and excellent surface quality.

PEEK

PEEK is a premium engineering plastic offering extremely high mechanical strength, outstanding heat resistance, and excellent chemical resistance. It maintains stable performance under extreme conditions and is an ideal alternative to metal and other plastics for demanding, high-precision CNC machining applications.

Processing Workshop

We offer you the capacity and expertise of dozens of local and global machine shops, and you can easily work with a single machine shop. You'll gain access to the experience and professionalism of all our partner shops; we handle all communications, delivery, quality control, and customs.

Application

We offer one-stop CNC machining services and understand the requirements of CNC machined parts in every industry, which gives us an advantage in handling our customers' special needs.

Robots

CNC machining can be used for robot parts, such as control connectors for arms, legs, and heads.

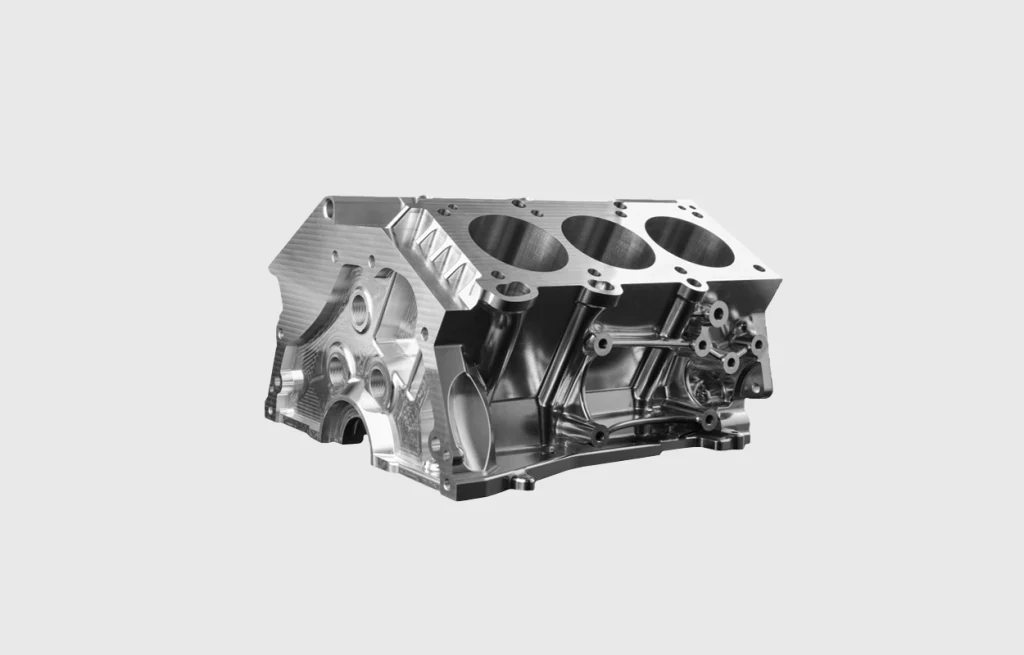

Automotive

CNC machining can be used for automotive engines, steering gears, bearings, wheel hubs, etc.

Medical Devices

CNC can manufacture medical device parts, consumable parts, high-precision parts, and linkage parts.

Machinery

CNC machining can manufacture mechanical equipment parts, wear parts, high-precision parts, and component parts.

Aerospace

CNC machining can manufacture aircraft engine parts, cabin linkages, etc.

Automation

CNC can manufacture power components, booster devices, chain links, etc., for automated equipment.